点胶新闻

Form In Place gaskets FIP点胶加工

来源:www.szgwind.com 发布时间:2017年05月14日

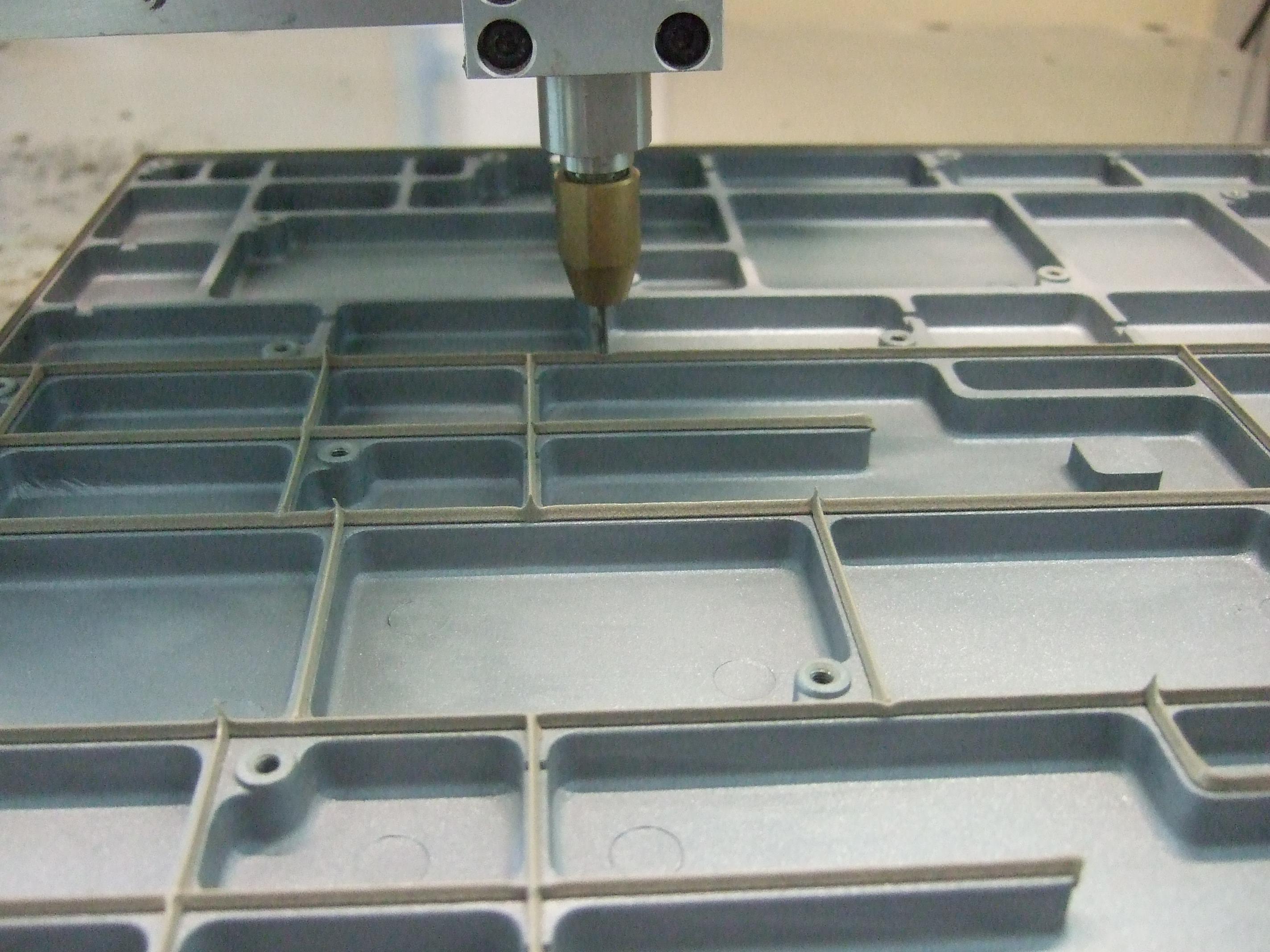

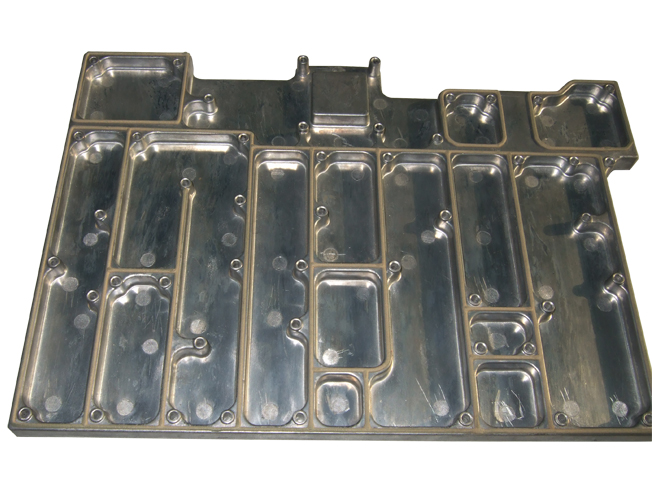

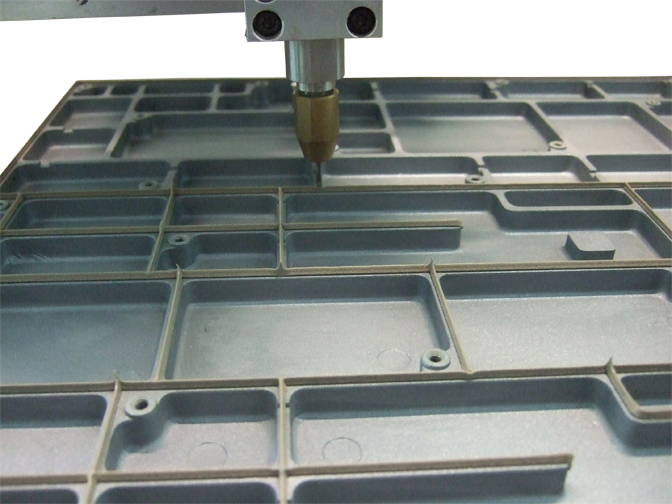

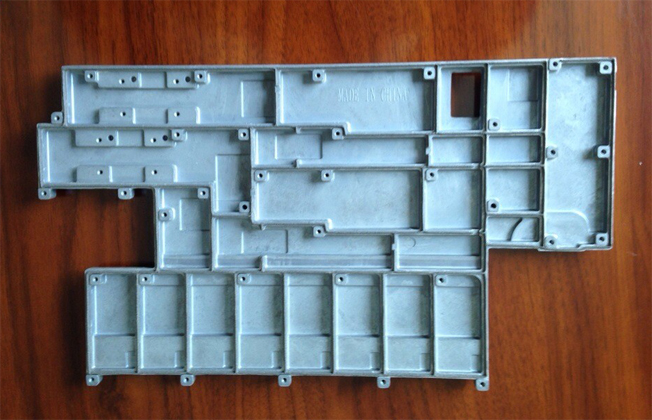

FIP点胶加工是指以精确的计算机操控自动化点胶设备,将流体硅橡胶直接点涂在金属或塑料的机壳表面,在一定条件下固化,从而形成密封胶条衬垫,以达到防水环境密封效果,IP65至IP67防水等级!并且点胶成形后,胶条直接粘于产品表面,有较强的附着力,方便产品安装和维修拆卸。FIP点胶加形成后使用的表现,是普通橡胶密封件使用寿命的三倍以上。

Gwind Tech Industries has been providing quality Foam in Place gaskets since 2006. Starting with a single Spuhl CNC Foam in Place robot and two employees located in a 1000 sq. ft. facility, Gwind Tech Industries has grown to 4 production lines running two shifts per day at their 8000 sq. ft. facility in ShenZhen,China. Gwind Tech Industries provides Foam in Place gaskets for it’s customers in the automobile, electrical enclosures, medical, filter, recreational vehicle,construction, and consumer product industries.

Contact us for a Quote

- Foam In Place gaskets applied directly to your parts.

- Foam In Place gaskets molded to your specifications.

- Foam In Place gaskets produced by CNC controlled robots.

- NEMA 4 seamless gaskets. Applied to your part or shipped to you for application.

- New Foam In Place dispensing equipment.

We offer silicone elastomer material from all major FIP producers including Nolato,Chomerics,Laird

Technologies,and Momentive.Moisture or thermal cure materials are available.

相关文章

- FIP点胶加工产品完成后的导电胶修剪规范2017年05月09日

- FIP点胶加工的工艺流程介绍深圳市神风行科技有限公司2017年05月08日

- 密封胶点胶加工和防水点胶的相关介绍2017年05月13日

- 全自动点胶加工的完善2017年05月12日

- 深圳市神风行点胶加工厂官网上线2017年05月12日